New York (CNN)Surging shopper demand coupled with shipping container shortages and bottlenecks at ports have already triggered tighter supply of products, from cars to shoes.

In particular, some of America’s biggest sellers of clothing and shoes cite one catalyst that has compounded the pressure: factory closures in Vietnam stemming from a second wave of the coronavirus outbreak there. That’s led brands from PacSun to Nike to warn about the effects on their supply.In late December, Nike (NKE) cut its full-year sales outlook due to supply chain issues, despite its CEO noting strong consumer demand.

Nike makes about three-quarters of its shoes in Southeast Asia, with 51% and 24% of manufacturing in Vietnam and Indonesia respectively.

But as the Vietnam government imposed pandemic-related restrictions, including a mandatory shutdown of factories for several weeks from July into September, Nike said it incurred 10 weeks of lost production.Read MoreEven when factories start to reopen, which the company expects to happen in phases beginning in October, ramping up to full production could take several months, Nike’s chief financial officer Matthew Friend said in a recent earnings call. Half of Nike’s clothing factories in Vietnam are currently closed, company executives said during that call. Vietnam accounts for a third of sports brand Under Armour’s footwear and clothing production. Under Armour (UA)’s CEO Patrik Frisk said during its most recent earnings call in August that it was closely monitoring impact of factory shutdowns there on its supply chain there, calling it a “developing situation.”

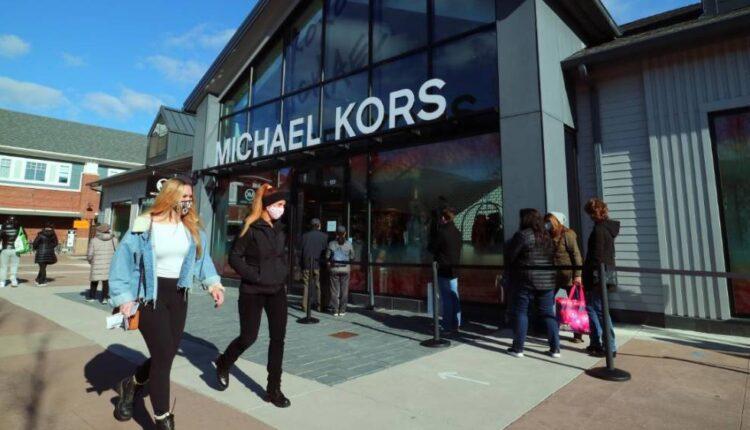

Ugg, Coach and Michael Kors have exposure

Vietnam is a crucial supplier to the US in particular for apparel and footwear. “It’s a very big partner of the United States. It’s our second largest source of apparel and footwear,” said Steve Lamar, president and CEO of the American Apparel and Footwear Association, an industry group. China is the largest supplier of clothing and shoes, according to the AAFA.Holiday bummer: Now prices are soaring for Christmas trees and decorationsIn July, Vietnam was caught in the throes of a coronavirus outbreak caused by a suspected new variant of the virus, which Vietnam’s health minister said led to a fast spread of new infections in the nation’s industrial zones.The government subsequently imposed strict lockdowns and temporarily shut factories there until mid-August, then extended it into September. Some factories are still closed.All of this means that production for everything from sneakers and sandals to jeans, dresses, T-shirts, jackets and more is stalled.In a research note last month, BITG analyst Camilo Lyon said athletic footwear brands such as Nike and Adidas are most at risk of having serious supply chain disruptions because “Vietnam has served as a strong manufacturing alternative to China in recent years.”

A number of popular brands such as Coach and Michael Kors manufacture products in Vietnam.Other brands that have significant manufacturing exposure to Vietnam, he said, include Ugg maker Deckers Outdoor (DECK), Columbia Sportswear, Coach parent Tapestry (TPR) and Capri Holdings (which owns the Michael Kors brand).Lyon estimates it may take five to six months for factories in Vietnam to be back up and running normally when the lockdown ends. And whenever they do come back on line, he anticipates another issue: staffing.”Vietnamese factories will also likely have trouble getting workers to come back to work post-lockdown,” he said. Teen retailer PacSun is expecting an impact to the holiday season. The workers who keep global supply chains moving are warning of a 'system collapse'Brieane Olson, president of PacSun, said in an interview in August with CNNBusiness that about 10% of its goods are sourced from Vietnam.Olson said the retailer was already dealing with a two-to-four week delay for its back-to-school inventory this year because of the ongoing global supply chain delays.

Now, she said, new products for the winter and holiday season is likely to also face another four-week delay, she said, making it a challenge to get new fashions and styles in jeans, tops, sweaters and sweatshirts into stores in a timely manner.And there’s an additional effect on the consumer, Olson said: Having less product means the retailer will pull back on discounts “because there is no need for it,” she said.

Source: edition.cnn.com